How do you decide which type of industrial robot is the right fit?

There are so many different types of robots on the market - how do you know which type to use? As with many design and engineering issues, “form follows function”. That is, which type of robot is needed depends on its intended function. Will the robot be fastened to the floor or other surface, or does it need to be mobile? How many units per hour must the robot be able to process? What's the maximum weight the robot must lift? If the robot is fastened in one place, what is the size of the work envelope? Is the work envelope rectangular or circular? Answering these and other questions will narrow down the selection and enable suppliers to propose robot solutions that match your purpose.

In this article, we examine different types of robots, their strengths and weaknesses, and their key application areas.

Contents of this article

- Stationary Robots (Robotic Arms)

- Autonomous Mobile Robots

- Flying Robots (Aerial Drones)

- Underwater Robots

- How to source the ideal robot type for your organization

Stationary Robots (Robotic Arms)

There are seven main types of stationary robots available on the market. By stationary, we mean robots that are bolted to the floor, the ceiling, or some other surface - they are not mobile. Generally, stationary robots are robotic arms designed for tasks like picking and placing, sorting, assembling, welding, and finishing.

Here we consider the different types of robotic arms, and their characteristics and uses.

- Articulated Robotic Arms

- Cartesian or Rectangular Robots

- SCARA Robots

- Polar or Spherical Robots

- Delta or Parallel Robots

- Gantry Robots

- Cylindrical

- Collaborative Robots/ Cobots

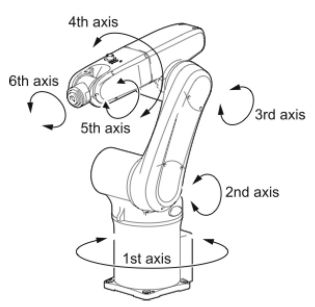

Articulated Robot Arms

Advantages: Most flexible movement of all the robot arm types. Can be quite powerful, capable of lifting heavy objects.

Disadvantages: Might need to be fenced off. Slower than some of the other robot arms. More expensive than other robot arms. Needs more sophisticated control systems.

In comparison with other types of robot arms, the movement of an articulated robot arm most closely resembles a human arm. A typical articulated arm has six axes, or joints. It may have fewer or more, depending on the application and manufacturer. The more joints a robot has, the more smooth and less “robot-like” its motion becomes. This flexibility of motion is described by Degrees of Freedom.

Interesting fact: Designers of artificial hands consider the human hand to have 27 degrees of freedom. A human arm has 7 degrees of freedom, for a combined total between the human arm and hand of 34 degrees of freedom.

To replicate all of the subtle ways the human arm and hand can move would be too expensive and complex for an industrial robot. It is generally agreed that 6 degrees of freedom in an industrial robot arm are enough for them to perform almost any task that is needed.

The robot will not be able to play the piano, but it doesn’t need to!

Depending on the application, a robot arm may be equipped with a gripper, the robotic equivalent of a hand. Usually, robot grippers are much simpler than the human hand. Sometimes they might be as simple as a suction cup or an electromagnet. Or, perhaps a three-fingered, soft gripper might be used to pick up delicate objects, like fresh produce or an egg. There are many different types of grippers, and no single robotic gripper has yet been found that can handle all applications.

Alternatively, the End of Arm Tooling (EoAT) as it is called, can be some kind of tool, perhaps a rotating tool that holds a drill bit, or some other kind of a bit, for deburring, grinding or milling. There are many possibilities, including specialized EoAT for welding, painting, sanding, laser cutting, and many more.

Articulated robots are highly flexible as all their joints can rotate, as opposed to linear or translational joints, which can only move in a straight line.

Articulated robots are used in applications such as pick and place, arc welding, spot welding, packaging, machine tending, and material handling. The ability to produce arcs (or similar patterns) in hard-to-reach places makes articulated robots a good candidate for the automotive industry and other manufacturing which requires this ability.

Historically, large and powerful articulated-arm robots capable of picking up objects weighing a ton or more were not equipped with sensors that allowed them to be aware of their environment. If a person were to get in the way of such a robot, they could be seriously injured or even killed.

As a result, such robotic arms need to be separated into a space of their own. Only qualified personnel who fully understand the functioning of the robot are allowed to enter the walled-off or fenced-off space within which such robots operate.

However, if an articulated robot arm is equipped with appropriate sensors and control software, it can safely operate around people. For example, using computer vision with a camera or perhaps a LiDAR sensor, if such a robot senses that something is in the way of its path of motion, or even that a person or object is approaching and not yet in the way, the robot can slow down or stop. Other sensors can detect a collision – if the arm bumps into something, it will stop and/or reverse course. Usually, articulated arms that are safe to operate alongside people are designed to be limited in their speed and strength.

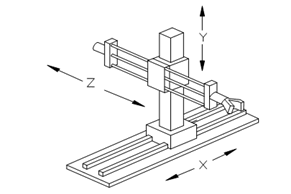

Cartesian or Rectangular robots

Advantages: Simple control system. Depending on the model, can lift very heavy objects. Accurate. Rigid in all three axes. Less expensive than articulated arms.

Disadvantages: Cannot do rotational movements.

These robots use the Cartesian coordinate system (X, Y, and Z) for linear movements along the three axes (forward and backward, up and down, and side to side). All three joints are translational, which means the movement of the joint is restricted to going in a straight line. This is why such robots are also called “linear” robots.

Cartesian robots can be used for pick-and-place, material handling, packaging automation, storage and retrieval, cutting and drilling, and many more applications.

They are rigid in all three dimensions, which makes them very accurate and repeatable. They are simpler than articulated robotic arms, with simpler software control, and can be less expensive, depending on the application.

Gantry Robots - A Type of Cartesian Robot

Advantages: Depending on the model, can lift very heavy objects. Can be made very large, spanning the entire length of the facility, if desired. Can be very cost-effective for the right applications.

Disadvantages: Cannot do rotational movement.

Cartesian or linear robots can be configured as gantry robots. Gantry robots move along an overhead track. Depending on their design, gantry robots can handle very heavy loads and move them quickly and precisely. They can also be made very large, if needed, covering the entire floor space of a facility. Smaller gantry robots can be useful for pick-and-place and other operations involving high accuracy and good rigidity.

Because the motion control aspect of the linear robot is relatively simple, it is often lower cost than other types of robots and can be a highly cost-effective solution for many automation tasks.

The work envelope of a Cartesian robot is rectangular. Adding the vertical movement means the work envelope is in the shape of a box.

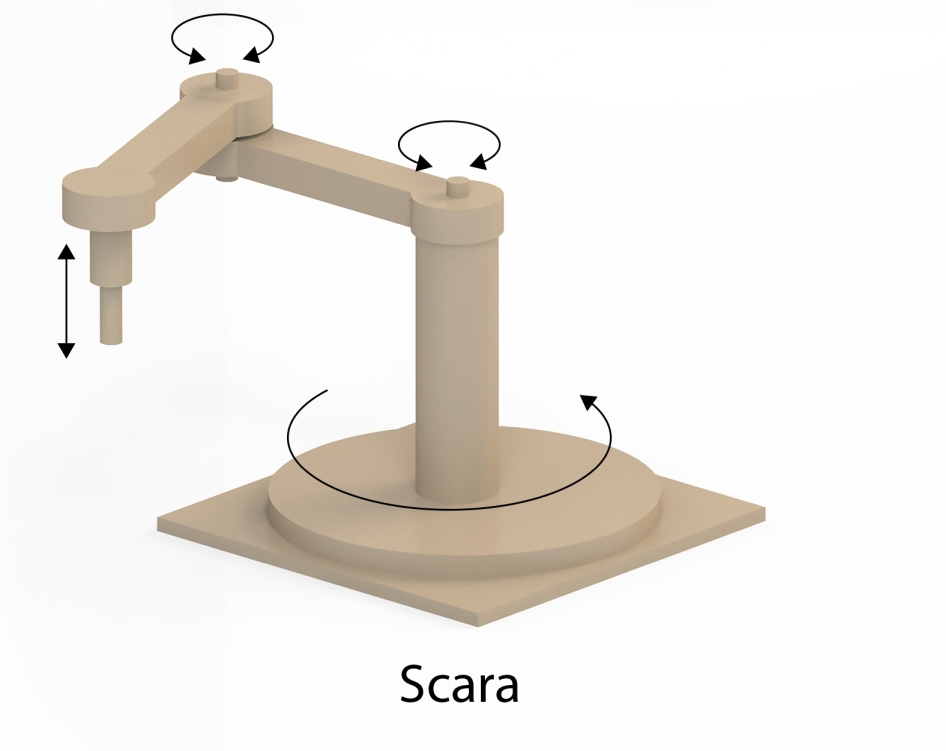

SCARA robots

Advantages: Excellent for many assembly applications. Fast and accurate. Cost-effective for assembly operations.

Disadvantages: Not as flexible as articulated arms. Not as accurate as Cartesian arms. Not as fast as Delta robot arms.

SCARA robots (Selective Compliance Assembly Robot Arm) are similar to Cartesian robots in that they move in 3 joints or axes. However, in contrast to Cartesian robots, two of the joints of SCARA robots are rotational. They are therefore capable of more complex movements than the Cartesian robots. They are generally faster and have more flexibility in movement but are less precise than Cartesian robots.

Interesting Fact: The widespread use of SCARA robots revolutionized the small electronics industry. Due to their small footprint, simplicity, and design characteristics, they are uniquely well suited for this application arena and have proven to be highly cost-effective.

As the “assembly” in the name implies, the SCARA robot arm was invented for assembly applications. The SCARA robot was created in 1981 by Hiroshi Makino at Yamanashi University in Japan. The “compliance” in the name refers to a certain amount of “give”. That is, if you push a SCARA robot in the horizontal plane, it will give a little - it will move, it’s not totally rigid. However, in the vertical plane, a SCARA robot is quite rigid, and it will not “give” if you push it in this direction. Therefore, it has “selective” compliance. It is compliant in the horizontal plane, and not in the vertical plane.

Selective compliance is quite useful in assembly operations in which a part needs to be inserted into a circuit board, for example. This kind of assembly often requires a part to be fit into a hole. Centering the part into the hole often needs a little “compliance” to find the center point - a little wiggling around, or a bit of “give”. Then, the insertion force, moving downward, needs to be firm and rigid.

SCARA robots are less rigid than Cartesian robots and are also limited to the weight they can lift, in comparison with the Cartesian robot which can lift quite heavy objects. SCARA robots have a small footprint and are generally used for applications in which the distances to be moved are relatively small. They have fewer degrees of freedom than the articulated arms. On the other hand, they have a high degree of accuracy and are quite repeatable. And they are less expensive than an articulated arm.

The work envelope of a SCARA robot is cylindrical, which is also a consideration when considering the application. SCARA robots are generally faster than articulated arms, although not as fast as Delta robots.

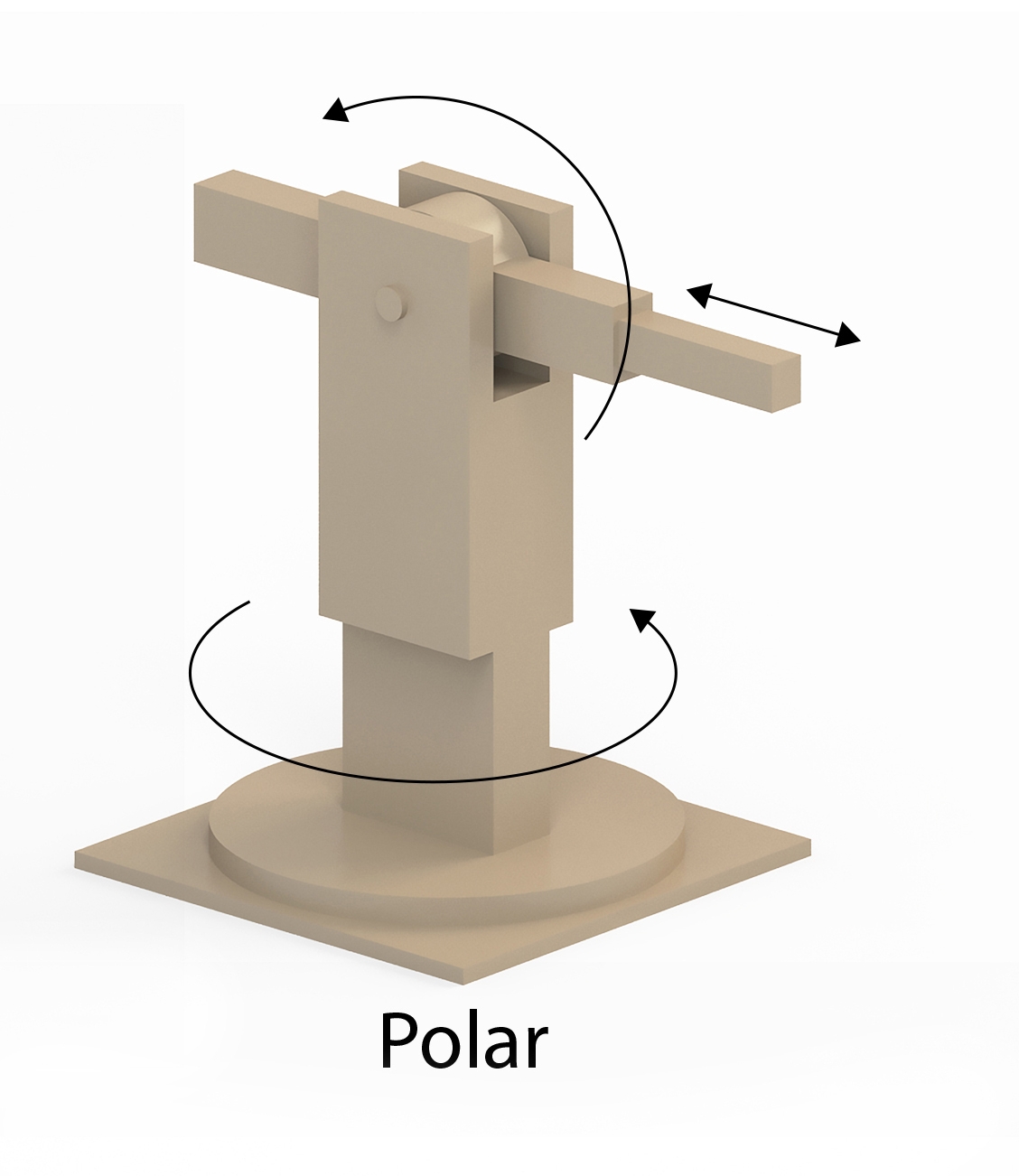

Polar or Spherical Robots

Advantages: Simpler control system than articulated arm. Can have long reach. Very good for many welding applications. May be faster than articulated arm.

Disadvantages: Not as flexible as articulated robot arms. Older technology. Often needs a rather large footprint. Not as fast as Delta arms.

Polar robots (sometimes called spherical robots) feature a combination of two rotational joints and one linear joint. Their design creates a spherical-shaped working space.

Interesting fact: The first industrial robot (created in the 1950s), called “Unimate”, was a spherical robot.

Polar robots can be used for injection molding, painting, arc welding, and spot welding. They can have a long reach when equipped with a suitably sized linear arm.

Polar robots are an older technology and can be replaced with articulated arm robots (which also have a spherical work envelope), although in some applications the polar robot may still be more cost-effective than its alternatives.

Delta robots

Advantages: Fastest design of robot arms for pick and place operations. Lightweight. Accurate.

Disadvantages: Limited to relatively small and lightweight objects. Not suitable for working on objects in a vertical plane. Limited reach.

Delta robots (also called parallel robots) have three robotic arms in the shape of parallelograms. Usually, the delta robot is located above the workpieces, attached to an overhead trestle. Because all the motors are on the base, the joints and arms of the robot are very light compared to other robots. The Delta robot has an upside-down dome-shaped work envelope.

Interesting Fact: The Delta robot was originally designed to enable a chocolate manufacturer to pick up pieces of chocolate and place them into a box.

The design of the Delta robot results in high-speed and precise operation. Delta robots are primarily used in pick and place applications. Additional applications include adhesive dispensing, soldering, and assembly. Delta robots cannot carry heavy payloads and that limits the types of End of Arm Tooling (EoAT) and the tasks they can handle.

Hybrid designs of Delta robots sometimes place rotating joints at the end of the arms to increase the flexibility of its motion.

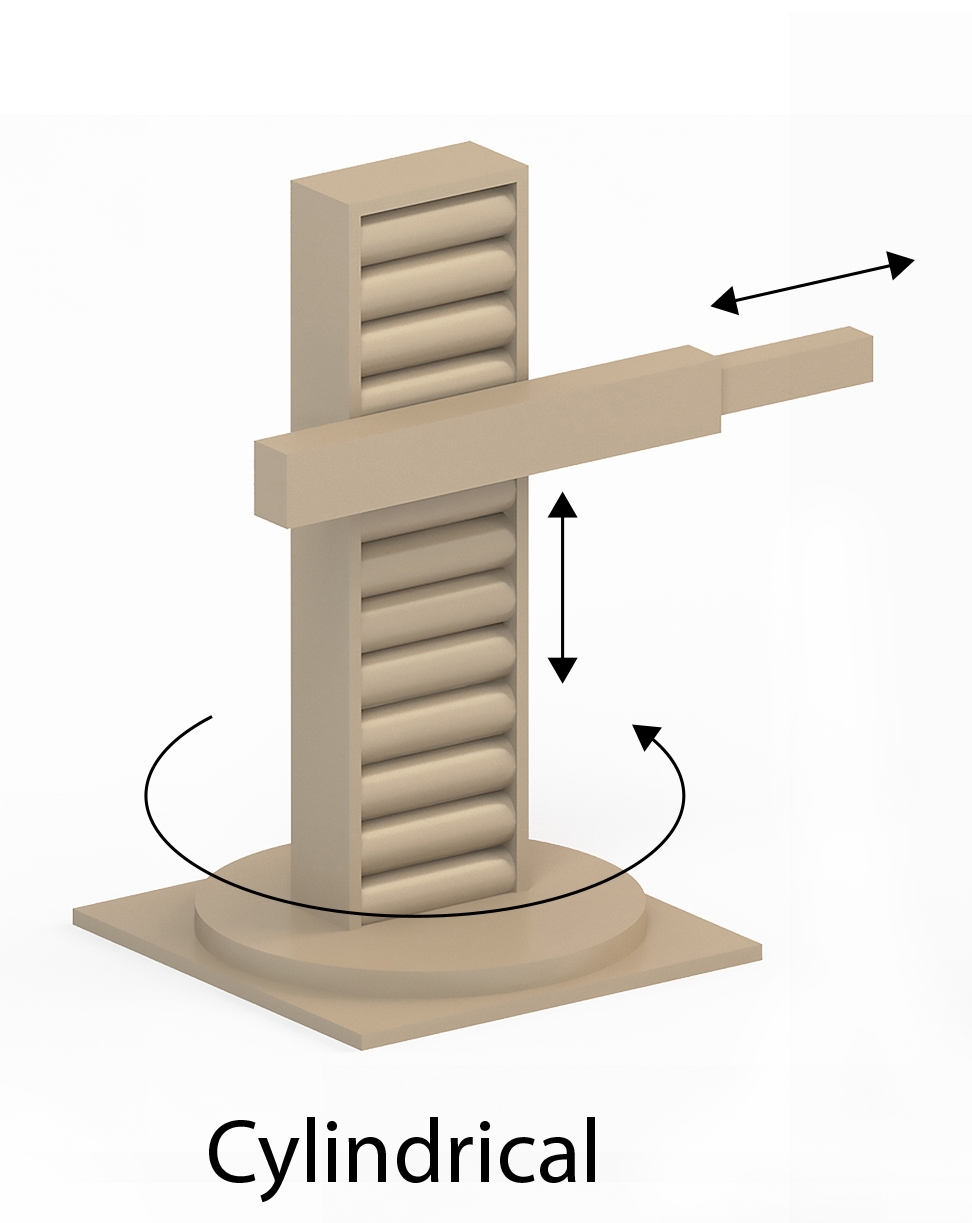

Cylindrical robots

Advantages: Rigid. Accurate. Perfect in applications that require circular geometry.

Disadvantages: Older technology. Limited flexibility of movement.

Cylindrical robots have at least one rotating joint at the base and two linear joints. This design leads to a cylindrical-shaped workspace.

Cylindrical robots are typically used in tight workspaces and they are a perfect fit for objects that need to have a circular symmetry (e.g wires, pipes). Grinding, assembly, and spot welding applications make use of cylindrical robots.

Collaborative robots (cobots)

Advantages: Safe to work alongside people. Modern interfaces allow “teaching” the robot arm what to do without writing code.

Disadvantages: Not always the fastest kind of robot arm. Limited in strength and speed.

Collaborative robots (cobots) enable human-robot interaction in a safe work environment, without the need for fences or other safety measures taken in traditional industrial robot applications. However, safety measures lead to a decrease in operation speed.

Apart from being safe to operate alongside humans, one of the features that make cobots more collaborative is the ability of an operator to teach the robot arm the movements to make without having to write programming code. The operator grabs hold of the robot arm and physically moves it in the way the robot needs to go. The robot arm can then replicate the demonstrated movement.

A standard cobot is typically not designed to handle very heavy objects. This creates a limitation on the range of products it can manage.

Collaborative robots have a wide range of applications like machine tending, pick and place, assembly, arc welding, but are generally not suited for heavy-duty applications or very high-speed tasks.

Autonomous Mobile Robots

AMRs or Autonomous Mobile Robots represent a rapidly growing segment of the industrial robot market. They come in many shapes and sizes, optimized for the tasks they are designed to perform.

Wheeled Carts

AMRs in the form of carts or vehicles with wheels are typically used for transporting goods within a factory or warehouse facility. They are equipped with sensors, onboard computing power, and electric motors that enable them to move around a facility and create an internal map of it. This is often done with a person following the AMR around, guiding it by remote control.

Once an internal map has been created, the AMR can then be instructed as to the destinations to which it needs to travel. A key feature of AMRs is that they can independently (“autonomously”) travel from one place to another, avoiding obstacles along the way. If a person, forklift, or other object is blocking their way, they can swerve to avoid the obstacle or even plan out an entirely new route to their destination.

The autonomous capabilities of AMRs make them very flexible in comparison to a conveyor system.

AMRs in the form of wheeled carts can be used individually to transport goods, and they can also be used as part of a swarm, or fleet of robots. Fleets of AMRs are used by Amazon, for example. Amazon uses what is called a “goods to person” configuration, in which each robot picks up an entire shelf of products and brings it to a person at an order-picking station. The person then picks the product(s) from the shelf and places it in a container for e-commerce order fulfillment.

Recently, advances in computer vision, artificial intelligence, and gripper technology have made it possible to replace the person at the picking station with an articulated robotic arm. In this case, the wheeled cart AMR brings the goods to the robot arm, for a robot-to-robot collaboration.

Autonomously Guided Vehicles (AGV)

AGVs are usually in the form of a vehicle with wheels, and they are an older technology than AMRs. They have less onboard intelligence and consequently are not as autonomous as AMRs. AGVs do not have the ability to make a map of a facility. Instead, they rely on paths laid down for them. The paths are defined by wires placed into the floor, or special tape, or other kinds of guides. If an AGV encounters obstacles in its pathway, it can only stop and call for help.

However, the distinctions between AGVs and AMRs are becoming increasingly blurred. AGVs are being given more onboard computing power, and some now do have the ability to go around obstacles in their pathway.

AMRs with Robot Arms

A Robotic arm can be mounted on top of a wheeled-cart AMR. This increases the flexibility of the robot and the variety of tasks it can perform. One application is to use such a robot for tending a whole row of machine tools. The robot can unload a finished part and load a new blank workpiece into one machine, and then move down the row and repeat the operations for a series of machines.

Legged Robots

Millions of people have seen the YouTube video of dancing robots made by Boston Dynamics and have therefore seen two-legged and four-legged robots. One industrial use for robots with legs envisions deploying them for package delivery. Another use case is for search and rescue operations.

Using legs instead of wheels has certain advantages. The legs enable the robot to travel over some kinds of terrain that carts with wheels would find difficult or impossible. Legs make climbing stairs possible, and getting into and out of a vehicle more easily than a cart with wheels could do.

Spherical AMRs

Autonomous Mobile Robots in the form of a sphere are commercially available and have special advantages over other form factors. The spherical AMR’s system components are sealed inside a durable shell. This makes them capable of operating in harsh environments. They can also float and travel over water. Spherical AMRs can be amphibious, traveling both on top of water and land.

The propulsion system of a spherical AMR is most commonly based on shifting the center of gravity.

The industrial applications for spherical AMRs are primarily in surveillance and remote inspection. Equipped with cameras and communication, they can transmit video back to the remote operator. For hostile environments that might have toxic gas or other dangerous conditions, a spherical AMR might be ideal.

Flying Robots (Aerial Drones)

Unmanned Aerial Vehicles (UAVs) or drones are being increasingly used for various industrial purposes. One application is to use drones in warehouses to take inventory. The drone can fly through the aisles of the warehouse and use computer vision to count the number of items in boxes on the shelves.

Depending on its design, an industrial drone can be a kind of Autonomous Mobile Robot (AMR), since some models can automatically detect obstacles and avoid them, and independently navigate their way to their destination. Some industrial drones can be given a “mission”, which might consist of flying over a strip mining operation, or an infrastructure project. The drone flies its mission autonomously and can record video of the project, or make certain measurements and record them. Such drones can be used to monitor the progress of construction projects.

Amazon and other companies are already making limited use of drones for the delivery of durable goods and groceries.

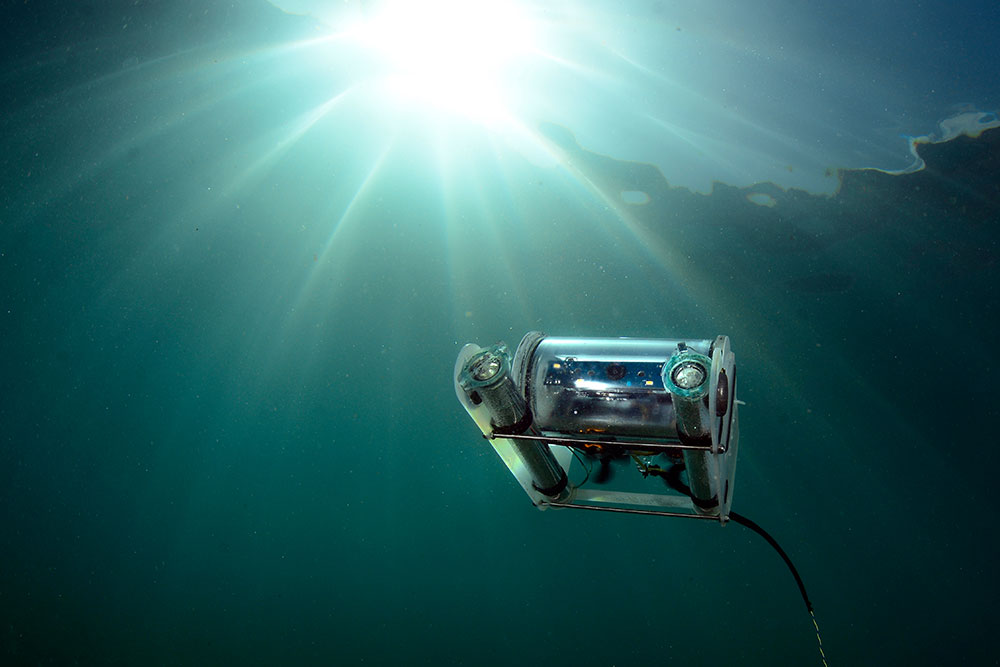

Underwater Robots

There are a wide variety of robots designed to be used underwater. Some underwater robots are designed to be autonomous (Autonomous Underwater Vehicles - AUVs), and some are made to be remotely controlled, either wirelessly or with a wired tether.

Some underwater robots use propellers as their propulsion system, similar to submarines. On the other hand, many such robots imitate the action of living creatures for their propulsion. Some mimic the action of dolphins, others imitate snakes, and still others move like fish. Imitating nature in this way is called “biomimicry” because the action of the robot mimics biological creatures.

Underwater robots can be used for inspection of offshore oil platforms, pipelines, and for scientific research. Other applications involve the use of underwater robots to inspect the bottom of bridges, inspecting hydroelectric dam intakes, and inspecting coral reefs.

Underwater robots are being used by police departments to take video recordings of the bottom of bodies of water looking for evidence. The military is also interested in underwater robots. Could a sonar system tell the difference between a robotic “dolphin” and a real one?

The advantages to underwater robots are many. Such robots mean it is not necessary to incur the risk and expense of human divers. Robots can stay submerged longer than people. Equipping underwater robots with sensors enables them to measure and record an almost infinite number and types of properties

How to source the ideal robot type

Before buying a robot, it is always a good idea to get an overview of what is available on the market and compare costs.

Rather than selecting a specific robot upfront, it is often recommended to first define and describe your needs, and then let the market tell you what is available and at what cost. This helps you get a solution that meets your specific requirements at the market price.

HowToRobot helps you gather and select relevant quotes from an extensive range of vetted automation suppliers. This allows you to quickly compare your options and make informed decisions.

Get quotes here

We also offer impartial advice to help you navigate the process and support your project from initial assessment to successful implementation.

See our advisory services and book a meeting with an expert advisor here