Supplier information

United States, Indianapolis

Integrator

10-19 employees

This supplier's business information has been validated by the supplier

Description

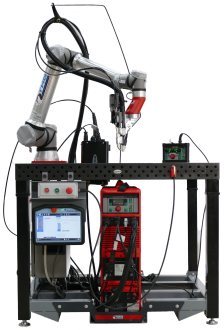

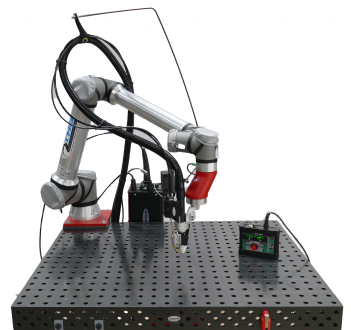

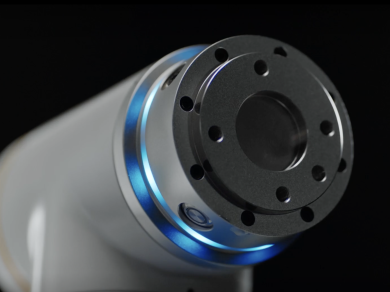

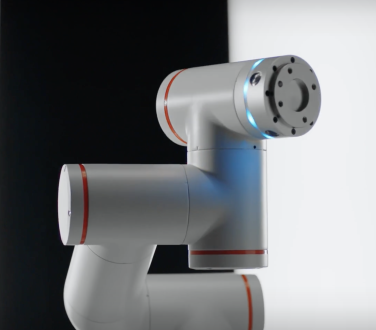

This system merges the collaborative robot capabilities of Universal Robots UR10e with industry-leading weld process control of Fronius MagicWave welding solutions. Once delivered, production welding can start in as little as a day, once powered up. A team with decades of experience in industrial robotic welding created the user interface to be easy to teach, employing powerful functionality, all with an intuitive interface.

All systems are capable of welding: Aluminum, Carbon Steel, Stainless Steel, Titanium, and many other materials.

Fronius offers a wide range of TIG functionality including: AD/DC power source, Push wire feed and Push-Pull for aluminum show here, remote pendant for live process editing, and much more.

This is our Fronius MagicWave 300 amp TIG welding system with push wire feed for autogenous or wire feed applications.

Weaving - Set the weave pitch, length, angle, dwell left, and dwell right.

"Z" Axis Tracking - Follow part deviation with ease.

100 weld jobs - Large welding job storage and access to those jobs at any point in the welding process.

Welding Simulation - Quickly turn welding simulation on and off while the welding program is running with a dedicated hand-held wand.

Copy and Pattern welding programs - Use Universal Robots Features to move, copy, or pattern welding programs.

Stitch weld, quickly set two points, weld length, and the number of welds to automatically create a series of strip welds.

Wire Feeding - Feed wire from a barrel or from the optional spool holder.

Starter kit of welding consumables including welding tips liners

Pendant Armor teach pendant protector

Screen Protector

Robot arm spatter guard system

Fronius specific tool kit

Free software upgrades for a year, including future options

Free phone support

Product details

Type

Robot Unit

Service agreement

Yes

Warranty

Yes

Training

Yes

Applications

Additional information

This supplier has not informed about any additional information

Video

Related products