Supplier information

United States, Algona

Component supplier

10-19 employees

This supplier's business information has been validated by the supplier

Description

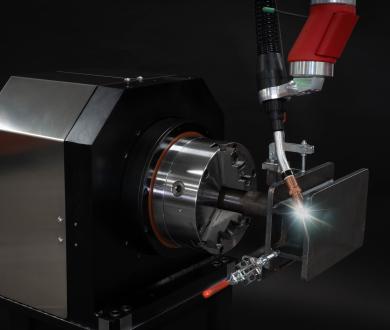

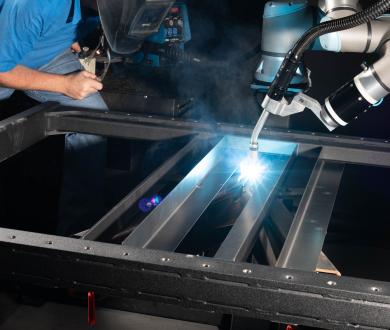

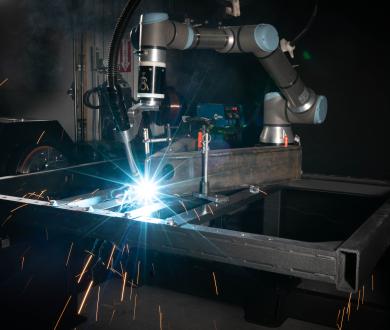

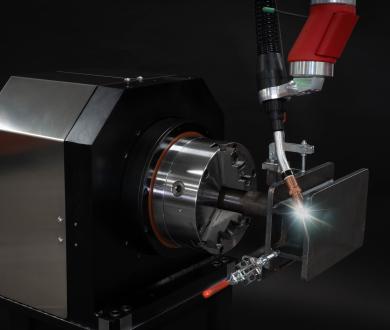

The robot controlled HT1 Headstock/Tailstock positioner dramatically increases your welding arc on time by presenting your part to the robot and then rotating the part to another position to weld the next sequence, decreasing manual manipulation and labor costs, all while increasing weld quality, accuracy, and repeatability.

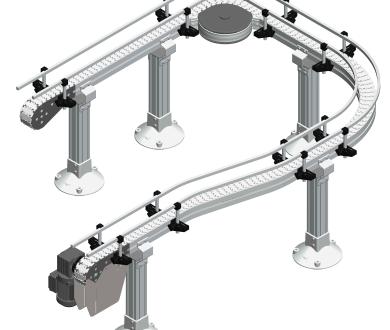

The HT1 has a small footprint and can be installed within a couple of hours. It is a modular positioner that can be setup as:

-A single HT configuration with work-holding envelope attachment

-A dual HT configuration (robot in the middle),

-A radial positioner (using the head unit only),

- Or customized and expanded according to your needs.

Standard Models:

HT1 (Designed for 51” robot reach)

HT2 (Designed for 69” robot reach)

Dual Configuration with a central robot

A radial positioner (only using the head unit)

Work holding envelopes:

HT1: 60" x 48"

HT2: 120" x 48"

Maximum part weight: 1 ton (depending on CoG)

Capacity specifications:

2,450 Nm start/stop torque

1,960 Nm maximum rated torque

9,800 Nm maximum momentary torque

Less than 1 arc min backlash (1/60th or .0166 degrees)

8,820 Nm maximum moment loading

Repeatability: Less than 0.005" datum location

Power requirement: Standard package equipped with 240V 3-phase

All positioners are modular and can be adapted to your needs.

Product details

Type

Process equipment

Service agreement

Yes

Warranty

Yes

Training

Yes

Applications

Additional information

Attachment

Size

756669 KB

Video

Related products