Supplier information

United Kingdom, Shefford

Distributor

20-49 employees

This supplier's business information has been validated by the supplier

Description

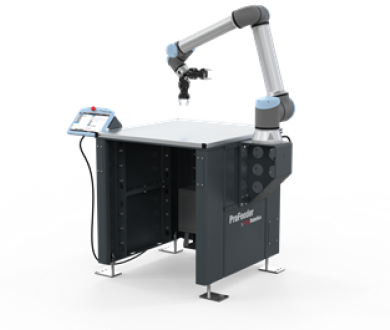

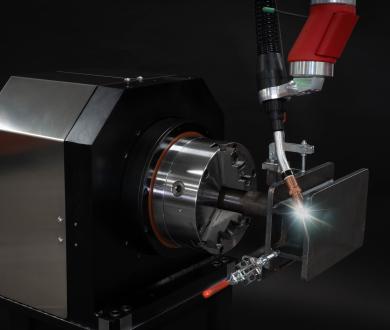

ProFeeder is a compact, modular robot cell that can be moved between production and processing machines to increase productivity. Designed to work with Universal Robots it can be systematically expanded in three steps from production automation of small series that can be upgraded, to full automation of large production series.

ProFeeder Light is the foundation product which comprises a basic, stand-alone unit with one manually removable parts’ tray with a capacity for up 780 units, depending on their size. Ideal for use with most CNC machines, ProFeeder Light can handle a wide variety of parts up to 10 kg and is used as extra ‘manpower’ for small batch production or the first step towards greater automation. It can also be expanded at any time to incorporate additional functions such as turning, deburring or cleaning.

The next in the three-model range is ProFeeder which comes complete with two movers and two parts trays. The mover is a modular cart which, when placed in the robot cell, automatically centres the parts tray. When the parts have been processed the first mover and tray are replaced by the second mover with unprocessed parts.

Interchangeable perforated plates in the parts’ trays ensure that the CNC machine can be fed with all part types and these can be replaced with thin plate feeding for operations such as edge bending or even a custom feeding solution.

This model is good choice for automatically loading a CNC machine, making it possible to introduce an additional shift. In the event of unscheduled downtime, the system automatically sends a text alert to the operator.

The third option is ProFeeder Multi that introduces a lift module that automatically presents trays to the machine for parts to be processed; its capacity is eight trays. This solution makes it possible to run a fully automated four-shift operation or even lights out production. Manual input is limited to machine supervision, pre-filling the parts’ trays and replacing the mover at the end of the fourth shift.

All ProFeeder systems can be quickly moved to a new station with a pallet truck. Set-up is easy and quick as it only requires connection to electricity and compressed air. The system’s compact design allows it to be used with most types of processing or production machine and, as the robot arm can be fixed on three sides of the cell, application flexibility is ensured.

Product details

Type

Process equipment

Service agreement

Partly

Warranty

Yes

Training

Yes

Applications

Additional information

Attachment

Size

4819681 KB

11440722 KB

Video

Related products