Supplier information

United Kingdom, Shefford

Distributor

20-49 employees

This supplier's business information has been validated by the supplier

Description

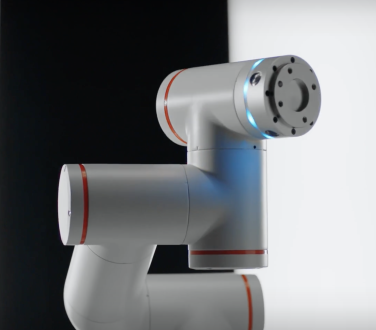

Palletising can be a very repetitive task when handled manually, this is why it is one of the most common robotic solutions across many industries. Our robotic palletising solution has been developed to meet the needs of companies providing essential goods in lower throughput applications, with frequent changes of task and box or pallet size. This palletising robot brings many benefits, including flexibility, efficiency and easy set up. It can also be easily integrated with other manufacturing lines, making automated palletising, depalletising, or both, a perfect solution to enhance your end-of-line operations.

How does the palletising system work?

An empty pallet is placed on the palletising machine

Boxes are moved into the palletising cell

Retro reflective sensors detect the boxes and the Universal Robot arm then picks them up and begins to stack them on the pallet

Once a pallet is full, the robot waits for the pallet to be removed, before it begins the process again.

What’s included:

Robot Base

Fully Integrated Vertical 7th Axis

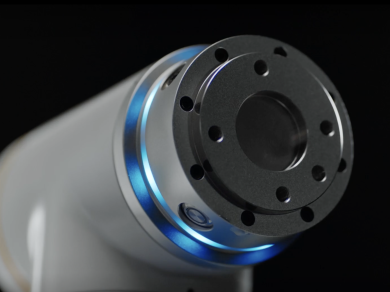

AirPick, Bracket, Suction Cups

Status Lights, Pallet and Box Sensors

Cable Management System

Application Software: Material Handling Copilot

What are the benefits of the Robotiq palletiser?

Quick and easy to install, set up and configure

All hardware and software already connected

Small footprint allows for an easy fit into an existing floor plan

Application set up on the robot in 3 simple steps

Fully integrated vertical 7th Axis

Palletiser can pick a wide range of boxes and cover extensive heights and pallet dimensions

Palletising software allows for a seamless and user-friendly experience

How does automating your end-of-line palletising enhance your operations?

Frees up your employees for higher value tasks

Provides a versatile and flexible option for palletising

Fast return on investment

Faster palletising speed compared to when the task is carried out manually

This robotic solution is the perfect application to ensure that all aspects of your end-of-line operations are highly efficient.

Product details

Type

Robot Unit

Service agreement

Partly

Warranty

Yes

Training

Yes

Applications

Additional information

Attachment

Size

Video

Related products