Supplier information

United States, Houston

Integrator

20-49 employees

This supplier's business information has been validated by the supplier

Description

The AI Pipe welding system pre-scans the weld joint using a 2D laser to measure the root opening, weld centerline, groove angle and groove volume. If the root opening is within weld-able limits, the system creates an optimized robot path with welding parameters. Our pipe welding software creates changes in the welding path, oscillation, travel speed, and welding parameters based off data learned from the laser scan. The program then finds an optimal position over a tack weld to start the arc ensuring 100% root weld acceptance. Fill and cap pass programs are optimized to fill the groove using user-selectable weave or stringer bead welding techniques.

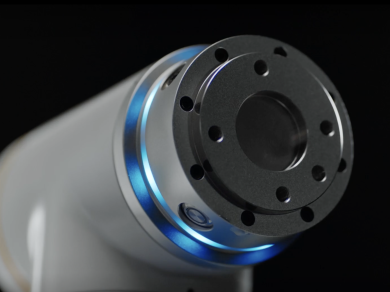

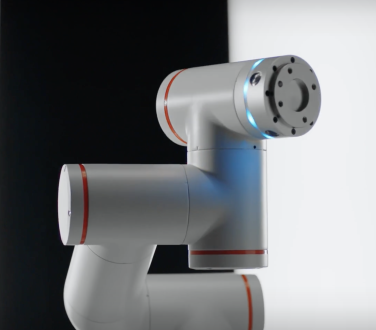

The system incorporates a 6-axis collaborative robot (Fanuc or UR). The cobot is light and compact enough to be portable while allowing full freedom of motion for both the laser scanner and the welding torch. As a collaborative robot, it is able to safely work in close proximity to operators. The Miller Auto Continuum welding power supply utilizes Regulated Metal Deposition (RMD) for the root pass and then switches to pulsed spray for the fill and cap passes. This combination of Gas Metal Arc Welding techniques maximizes weld productivity while producing x-ray quality, full penetration pipe welds.

Product details

Type

Robot Unit

Service agreement

Yes

Warranty

Yes

Training

Yes

Applications

Additional information

This supplier has not informed about any additional information

Video

Related products