Supplier information

United States, Chester

Integrator

10-19 employees

This supplier's business information has been validated by the supplier

Description

IF YOU ARE UTILIZING MOBILE INDUSTRIAL ROBOTS (MIRS), AUTOMATED GUIDED VEHICLES (AGVS), OR ANOTHER TYPE OF AMR ADDING A PALOMAT AMR PALLET MAGAZINE IS THE NEXT LOGICAL STEP IN OPTIMIZING YOUR FACILITY.

You need it, but what exactly is it? It is a bit confusing, because in the US “magazine”, “stacker”, and “dispenser” are somewhat interchangeable; but “magazines” are for storing and dispensing pallets with automated systems. The term “stacker” or “dispenser” is usually used for manual applications.

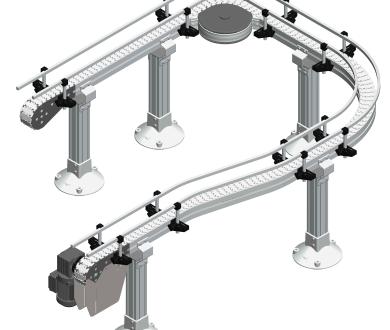

However, we have solutions for both processes because PALOMATs can be either standalone or integrated with other equipment to improve material handling processes, like with the PALOMAT AMR and AGV. You can find more information on those options in the download section.

Our PALOMAT AMR unit automatically stacks and destacks pallets onto an AMR. So it functions as a pallet buffer and docking station. It maintains a consistent pallet flow, and removes the possibility of pallets becoming obstacles or tripping hazards. Additionally, pallet magazines free up employees from having to manually load and unload AMRs. The PALOMAT AMR provides the same benefits as a stand alone unit by reducing likelihood of workplace injuries. PALOMAT AMR pallet magazines can hold up to 15 pallets, and have a cycle time of 10-15 seconds.

Each AMR pallet magazine we provide comes with a WISE 4060 module with I/O signals to easily integrate with a variety of AMR units. Power requirements are simple – units need 220-240VAC 50Hz 1P+N+PE.

A PALOMAT AMR pallet magazine is CE approved, and is compliant with the latest machinery directive.

Product details

Type

Process equipment

Service agreement

Yes

Warranty

Yes

Training

Yes

Applications

Additional information

Attachment

Size

1010614 KB

4021297 KB

1845628 KB

2243263 KB

1714034 KB

Video

Related products