Supplier information

Denmark, Hvidovre

Robot manufacturer

10-19 employees

This supplier's business information has been validated by the supplier

Description

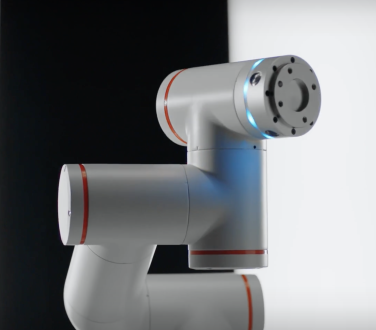

The J1600 self-driving pallet jack from The Mobile Robot Company is a dual-mode, collaborative material handling solution designed to bridge the gap between fully manual pallet transport and complex, capital intensive automation. It is built to operate seamlessly in dynamic warehouse, production, and logistics environments where flexibility, safety, and fast deployment are critical. The J1600 can be used exactly like a conventional electric pallet jack with full manual control via the tiller handle, while also offering autonomous driving capabilities that allow pallets to be transported automatically between predefined locations. This human-in-the-loop approach enables companies to automate repetitive internal transport without giving up the adaptability and intuitive control operators rely on every day.

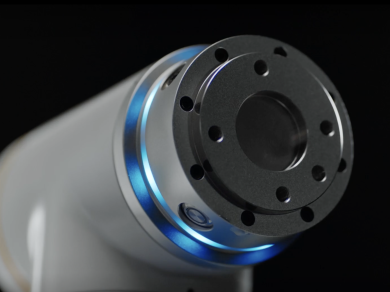

At the core of the J1600 is a robust autonomous navigation system based on 3D LiDAR SLAM technology combined with an industrial NVIDIA Jetson AI computer and an RGB camera. The robot continuously learns its surroundings as it is manually driven through the facility, eliminating the need for maps, reflectors, floor markers, or complex system integration.

New pickup or drop-off locations are created simply by driving the robot to the desired spot and saving the location on the integrated 15-inch multi-touch HMI. Tasks are launched directly from the touchscreen and can include simple point-to-point deliveries, multi-stop routes, return-to-operator missions, or calling the robot to a specific location. Wi-Fi connectivity is optional, and the system is ready to use out of the box without any IT infrastructure.

The J1600 is engineered for demanding industrial use and offers a rated payload capacity of 1,600 kg. It supports manual pallet pickup and drop-off up to a lifting height of 1.6 meters, while autonomous pallet delivery is performed at floor level. The fork geometry is optimized for standard logistics flows, with 1,150 mm fork length, 680 mm outer fork distance, and compatibility with EPAL Euro pallets, GMA pallets, and other open-bottom pallets or custom load carriers within size limits of up to 1,250 mm by 1,250 mm including load overhang. Maximum load height from floor is 1,700 mm, making it suitable for a wide range of goods and packaging types.

In operation, the J1600 reaches a top driving speed of 5.4 km/h and maintains smooth, predictable motion even when fully loaded. Fork lifting and lowering speeds are optimized for safety and stability, with lifting speeds of 0.1 m/s without load and 0.08 m/s at full load. The lithium-iron-phosphate battery system operates at 24 V and 200 Ah, offering long operational endurance, stable performance, and fast charging. Typical battery consumption is approximately 13 percent per hour when driving fully loaded, 12 percent per hour without load, and only 2 percent per hour in standby. Automatic charging is supported, enabling continuous operation with minimal operator intervention.

Safety is a fundamental design principle of the J1600. The robot is equipped with a comprehensive safety architecture that includes dual 2D safety LiDAR scanners, a 360-degree safety field, safety-certified motor controllers, speed and direction encoders, emergency stop buttons, load detection, and intelligent safety field adjustment. The system is designed to navigate safely among people, with obstacle detection and controlled stopping behavior that meets or exceeds relevant safety performance levels. The J1600 is CE marked and complies with key European and international standards, including EN ISO 3691-4, EN ISO 13849-1, and ANSI/ITSDF B56.5, making it suitable for deployment in both EU and US facilities.

Physically, the J1600 has a compact footprint that allows it to operate in narrow aisles and crowded work areas. The vehicle length is 1,893 mm, width is 850 mm, and the turning radius is 1,501 mm. Ground clearance is 30 mm, and the system is designed for indoor use on industrial floors meeting standard flatness requirements. It can handle small bumps up to 25 mm and gaps up to 20 mm, and operates reliably in temperatures from 5 to 40 degrees Celsius.

Manufactured in Denmark, the J1600 reflects The Mobile Robot Company’s focus on practical, accessible automation that delivers value from day one. By combining manual pallet handling with autonomous transport, the J1600 can reduce manual driving time by up to 80 percent, freeing operators to focus on higher value tasks while maintaining full operational flexibility. It is an ideal solution for companies seeking a fast return on investment, minimal disruption to existing workflows, and a safe, future-ready approach to internal logistics.

Product details

Type

Robot Unit

Service agreement

Yes

Warranty

Yes

Training

Yes

Applications

Additional information

Video

Related products